Industrial news

What plastic common usefor CNC machining

Although most plastic materials cannot be machined due to their rigidity and low melting point, we selected a group that has a wide range of CNC applications.

Acetal (POM)

Acetal is a highly versatile CNC plastic with a range of desirable properties. It has excellent fatigue and impact resistance, good toughness and a low coefficient of friction. Additionally, it is highly resistant to moisture, making it an excellent choice for use in humid environments.

One of the main advantages of acetal is its rigidity, which makes it easy to process and has high dimensional accuracy. This makes it a popular choice for precision components such as bearings, gears and valves. Due to its excellent mechanical properties and high resistance to environmental factors, acetal is a reliable choice for various industries including automotive, aerospace and consumer goods.

Acrylic (PMMA)

Acrylic is a commonly used material that can be used as an alternative to glass due to its ideal properties. It has good rigidity and optical clarity, allowing it to be used in applications requiring a transparent surface. Acrylic parts offer an attractive and functional alternative to glass, with good optical clarity and a high degree of durability.

While acrylic has some limitations, such as its tendency to crack and soften with heat, it remains a popular material for CNC machining due to its versatility and ease of use. Acrylic's ability to create precision, high-quality components makes it an excellent choice for a wide range of applications. Lenses, clear casings, food storage containers, and decorative items are just a few examples.

Polycarbonate (PC)

Polycarbonate (PC) is a popular plastic material for CNC machining due to its unique properties. It is highly transparent, making it an ideal material for products requiring clarity, such as safety glasses, medical equipment and electronic displays. In addition, it has good heat resistance and is therefore suitable for high temperature applications.

However, its tendency to scratch and lack of UV resistance limit its use in certain applications. Prolonged exposure to sunlight can cause it to turn yellow and become brittle. This limits its use in outdoor applications unless it is modified with UV stabilizers.

A common use for PC is in the production of safety glasses and face shields, where its impact resistance and clarity make it ideal. PCs are also used in the production of automotive parts, electronic components, and medical equipment.

Polypropylene (PP)

Polypropylene is a versatile polymer with many advantages, including high chemical resistance and fatigue strength. It is also a medical-grade material that produces a smooth surface finish when CNC machined. However, one of its limitations is that it cannot withstand high temperatures as it tends to soften and wear away during the cutting process, making it slightly challenging to work with.

Polypropylene continues to be a popular choice for a variety of applications. Its excellent properties make it suitable for making gears and medical products.

ABS

ABS is an extremely cost-effective plastic material that is well suited for CNC machining due to its excellent processability, tensile strength, impact resistance and chemical resistance. Additionally, it can be easily tinted, making it ideal for applications where aesthetics are important.

However, ABS is not suitable for use in high-temperature environments and is not biodegradable. Additionally, it produces unpleasant smoke when burned, which can be a problem in CNC shops.

ABS is widely used and is often used in 3D printing and injection molding, and is usually post-processed using CNC machining. It is frequently used to manufacture automotive parts and protective shields, as well as for rapid prototyping.

Nylon

Nylon is a versatile material with excellent tensile strength, stiffness and impact resistance. It can be used in a variety of composite forms such as fiberglass reinforced nylon and has excellent surface lubrication capabilities. However, use in humid environments is not recommended.

Nylon is particularly suitable for applications where friction needs to be prevented. This includes components such as gears, sliding surfaces, bearings and sprockets. Due to its superior strength and lubrication properties, nylon is a popular choice for many industrial and sports-related products.

ultra high molecular weight polyethylene

UHMWPE is a popular material because of its superior properties, including high hardness, wear resistance, and durability. However, its thermal instability during processing makes its processing challenging.

Although difficult to machine, UHMWPE is an excellent material for CNC machining of sliding surfaces in bearings, gears and rollers. Its outstanding properties make it ideal for applications requiring high wear resistance and durability. When processed properly, UHMWPE can provide excellent performance and longer life than other materials.

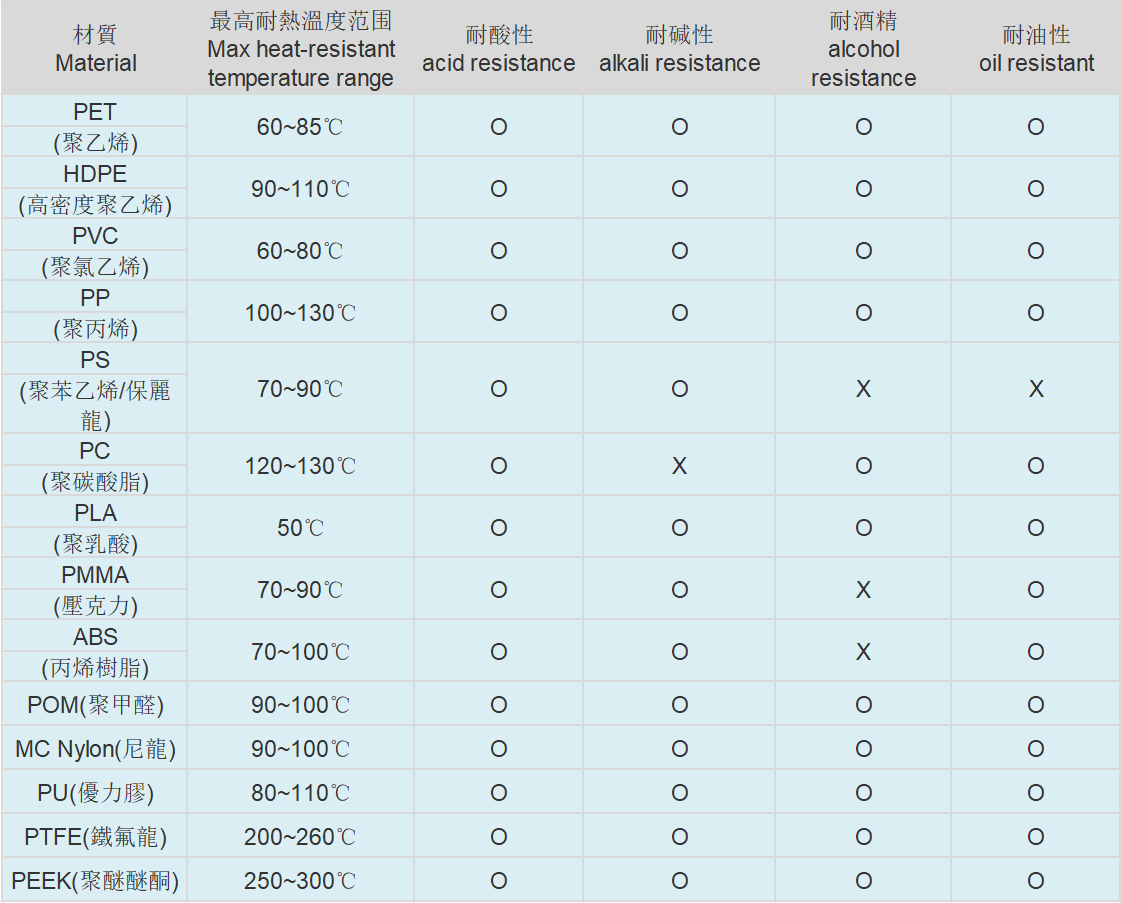

14 kinds of CNC processing common plastic material properties

Other materials

CNC machining typically works with metals and plastics, but it can also machine many other materials, including those listed below.

Foam

Foam is a CNC material characterized by a solid body with air-filled voids. This unique structure gives the foam a recognizable shape and extraordinary lightness. Certain high-density foams, such as polyurethane foam and polystyrene foam, are easy to process due to their rigidity, strength, light weight, and durability.

The lightweight nature of foam makes it an excellent choice for protective packaging. Their versatility in processing into a variety of shapes and sizes makes them equally suitable for making decorative items. Additionally, their thermal insulating properties make them a popular choice for insulation in buildings, refrigeration units and other applications where temperature control is important.

Wood

Wood is a widely used material in CNC machining due to its ease of processing, good strength and hardness, and wide range of available types. Additionally, wood is an organic compound and has no negative impact on the environment. Due to its versatility and aesthetic appeal, wood is a popular choice for furniture, home decor, and DIY projects.

However, wood processing produces large amounts of dust, which poses a health risk to workers. It is therefore important that woodworking shops have a proper chip management system.

Composite materials

Composite materials are materials composed of two or more components that are joined together by a bonding medium. Common composite materials used in CNC machining include carbon fiber, plywood, fiberglass, and more. These materials have applications in a variety of industries including automotive, aerospace, sports and medical.

Machining composite materials can be very challenging due to a variety of factors. The constituent materials in composites can have different mechanical properties and forms, such as fibers, chips or sheets. What's more, the bonding media themselves may have unique properties that need to be considered during processing.

Related News

- What differences of Laser welding and ti 2023-10-26

- What meateiral suitable and what should 2023-10-12

- Common CNC metal machining materials 2023-09-15

- What is the difference of processing bet 2023-08-28

- How to demould the screw thread structur 2023-08-08

Categories

Contact us

Suntime Precision Mould Manufacturing Co., Ltd.

Contact:Victor Li

Mobile:+86 18098979853

Email:info@suntime-mould.com

Add:Block A, Sihai Yunchuang Building, Hou Ting community, Sha Jing Street, Bao An district, Shen Zhen, Guang Dong of China. Post code: 518104