Industrial news

How to demould the screw thread structure?

In plastic parts, many industrial products and civilian products have internal and external thread designs.

Solving the problem of thread stripping of plastic parts is the key to this type of mold production.

Generally speaking, there are 2 types of methods to deal with the thread problem of plastic parts:

One is to use the method of force demoulding when the plastic parts and resin allow it;

Another type is plastic parts with deep threads, high resin strength and high thread precision requirements, and the method of rotating and pulling out must be used.

In the rotary dethreading structure, there are 2 types: manual dethreading and auto unscrewing.

Manual dethreading has low production efficiency, but the mold structure is simple and suitable for small batch production;

Automatic unscrewing has high efficiency and stable quality, and is suitable for mass production. In the structure of the automatic rotary dethreading mold, the reliability, stability and practicability of the structural design must be solved.

Automatic unscrewing has high efficiency and stable quality, and is suitable for mass production. In the structure of the automatic rotary dethreading mold, the reliability, stability and practicability of the structural design must be solved.

Today we mainly introduce the automatic demoulding method of the internal thread of the product.

The product has an automatic demoulding method for internal threads, generally using screw, hydraulic motor, hydraulic cylinder with rack...

Drive method. Each of the above methods has advantages and disadvantages.

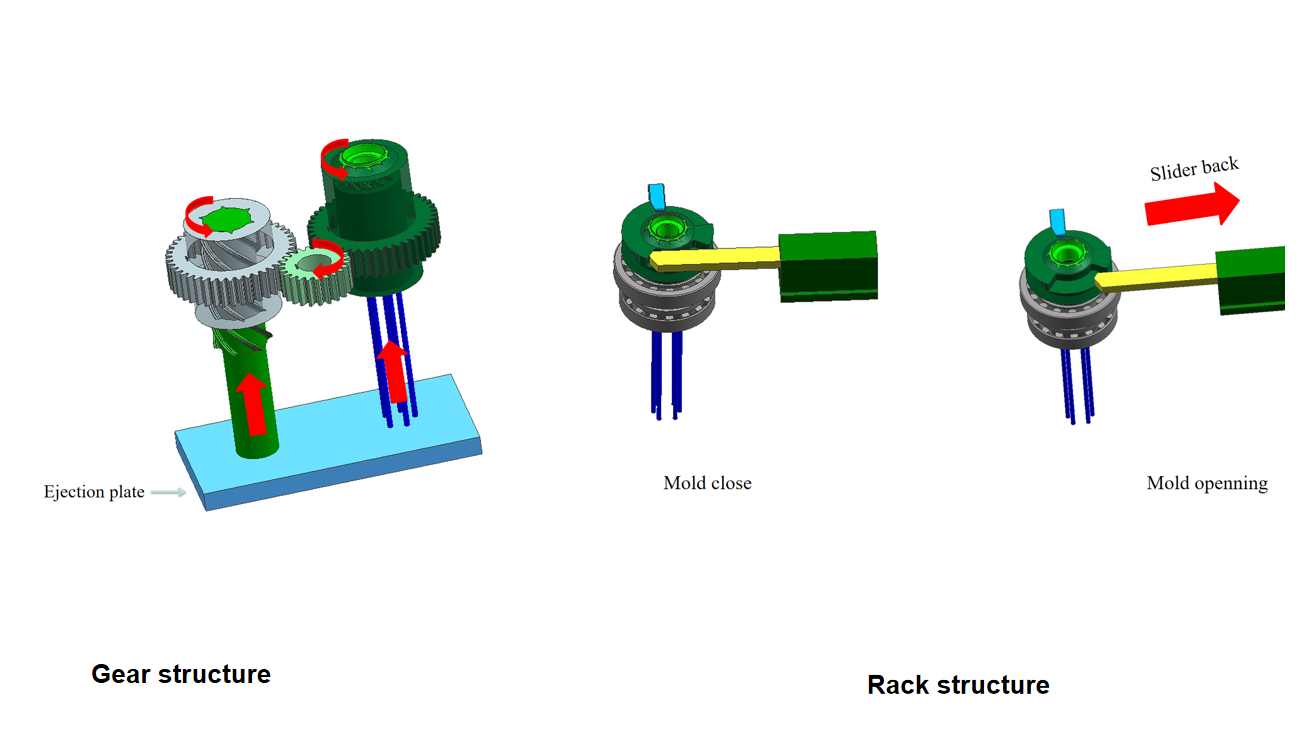

1,According to the action type:

①The threaded core rotates, and the push plate pushes the product out;

②The threaded core rotates and retreats at the same time, and the product is naturally separated.

2. According to the driving mode:

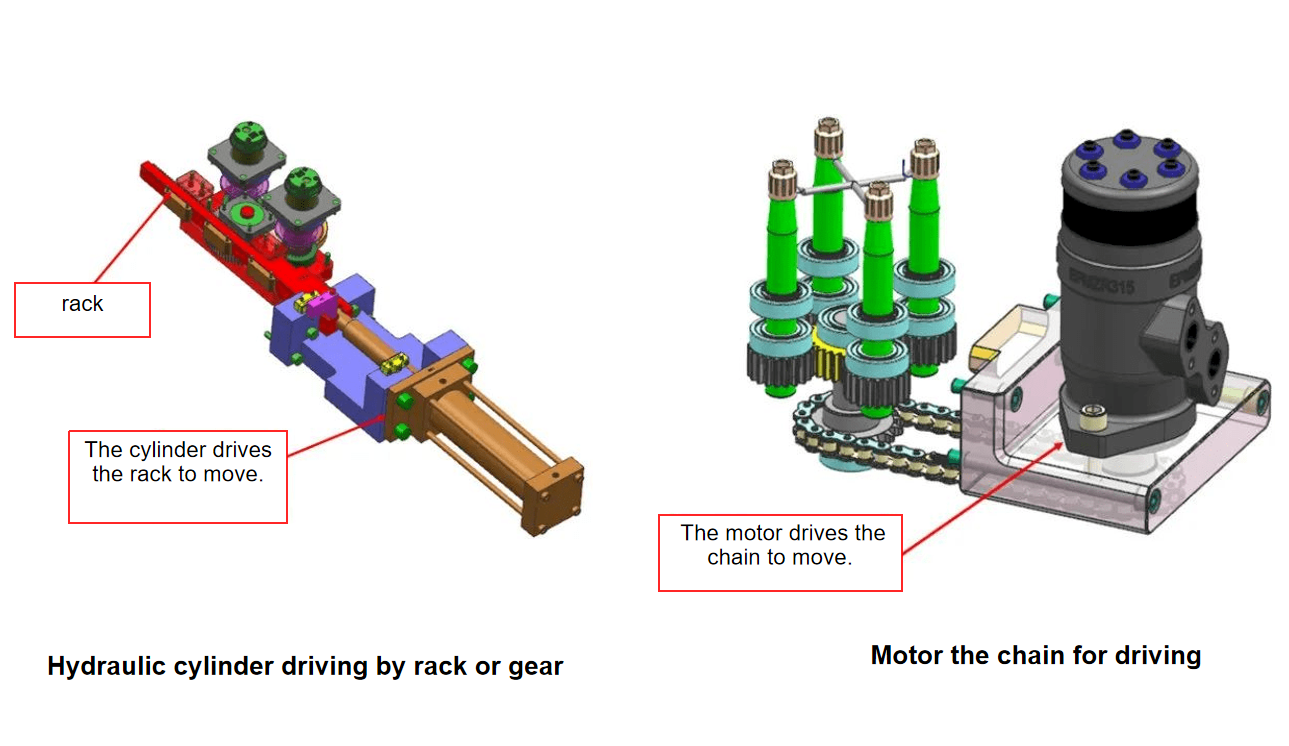

There are generally 2 types of thread demoulding molds: one is that the cylinder drives the rack to move, and the other is the motor drives the chain to move.

A. The screw structure includes: multi-head screw, supporting copper nuts, gears... But the screw and nut are extremely difficult to machining, and the pitch is usually 55- -80mm, 5, 6 screw, DME, HASCO have standard parts for sale. The price is expensive, but there are copy on the market.

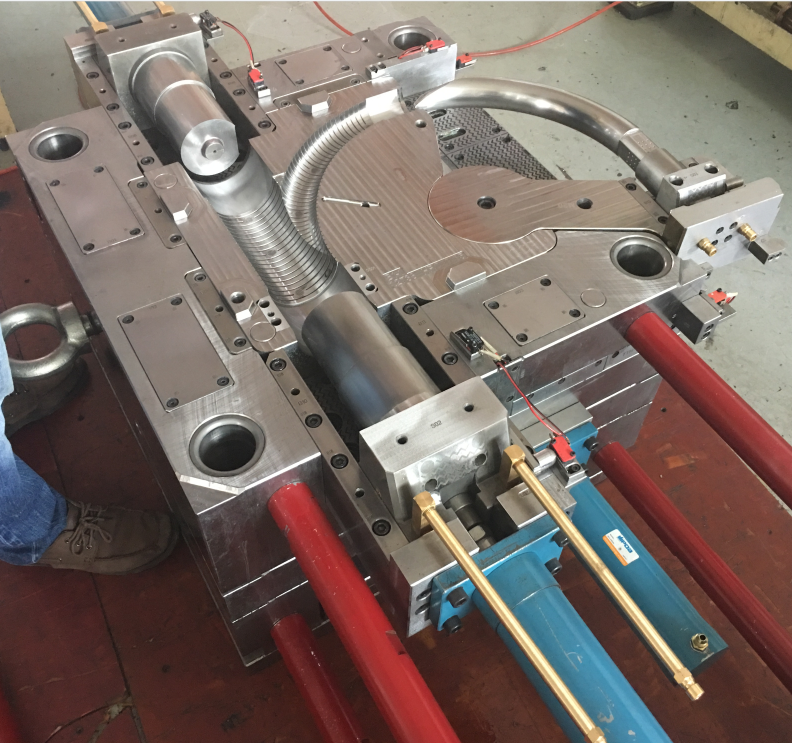

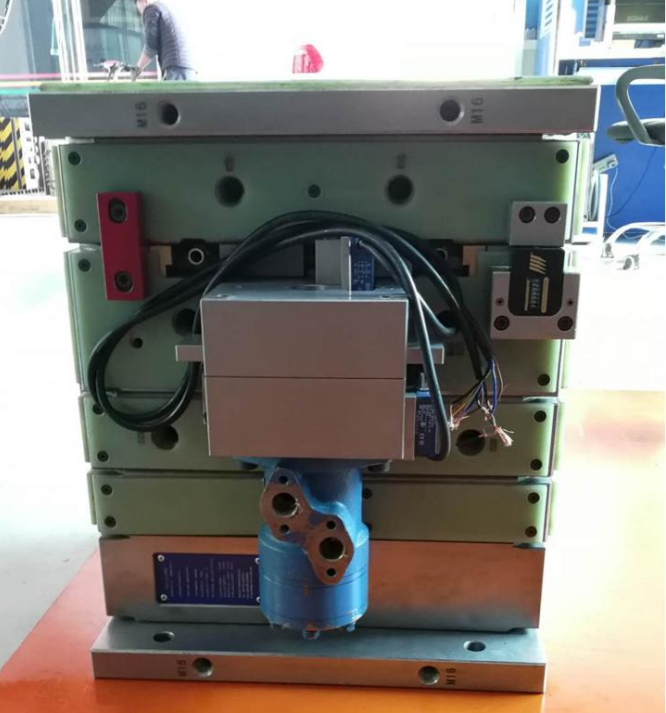

B. Hydraulic motor: There are standard parts for sale. It is often used when the product has a large number of threads and the outer circumference of the product is locked.

C.Hydraulic cylinder with rack: It is only suitable for the case of a small number of thread teeth (such as 2 to 4 thread. .) If the number of thread is large, a larger transmission ratio must be selected, resulting in a larger mold blank. If the transmission ratio is small, the stroke of the cylinder is too long.

Generally speaking, we will comprehensively consider the driving method according to the anti-rotation method of the product and the number of teeth of the thread.

SPM are familar for this kind of mold components and molds making, if interested, please contact for inquiry.

Related News

- What differences of Laser welding and ti 2023-10-26

- What meateiral suitable and what should 2023-10-12

- Common CNC metal machining materials 2023-09-15

- What plastic common usefor CNC machining 2023-09-04

- What is the difference of processing bet 2023-08-28

Categories

Contact us

Suntime Precision Mould Manufacturing Co., Ltd.

Contact:Victor Li

Mobile:+86 18098979853

Email:info@suntime-mould.com

Add:Block A, Sihai Yunchuang Building, Hou Ting community, Sha Jing Street, Bao An district, Shen Zhen, Guang Dong of China. Post code: 518104