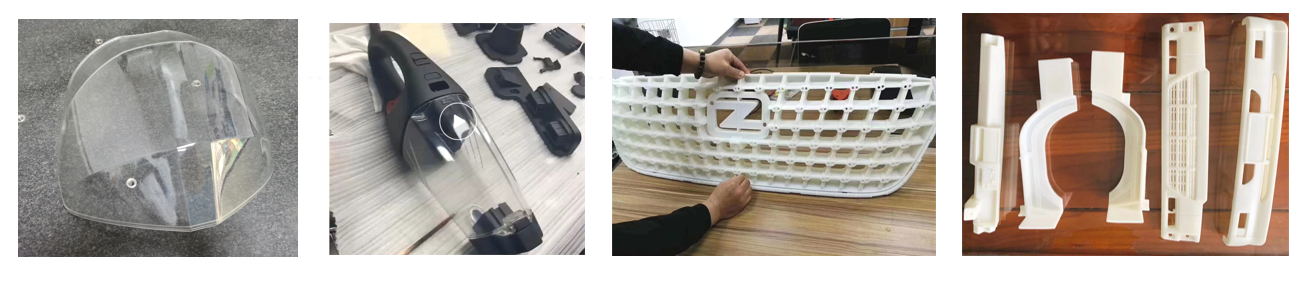

Rapid Prototyping

Material: Photosensitive resin composites

Processing: SLA 3d Priniting

MOQ: 1PCS

Exported market: USA

Customized design

3D printing prototypes is mainly process for samples making in innitial stage for a project, it's more flexible, fast and cost effective.

Advantages of 3D printing process:

1.Save material. There is no need to clean and remove scraps, which improves the utilization rate of materials and reduces costs by replacing abandoned production lines;

2. It can achieve extremely high precision and complexity, and can manufacture very complex manufactured parts that cannot be manufactured by traditional methods;

3. It does not require traditional tools, fixtures, machine tools or any molds, and can directly generate visual products from 3D CAD graphics of any shape on the computer;

4. It can automatically, quickly, directly and relatively accurately convert the 3D design in CAD into an actual model, and even directly manufacture parts or molds, thus effectively shortening the product development cycle;

5. 3D printing centralized consumption, fixed manufacturing workshop, has the characteristics of decentralized production;

6. 3D printing can be shaped within hours or day, which enables designers and developers to realize a leap from model to entity; it can print good products, so it reduces construction costs.

However there's also any disadvanges of 3D printing process as below.

1. Material limitations.

Take a closer look at some of the objects and equipment around you, and you'll see the first stumbling block to 3D printing, which is the limitation of the materials needed. Although high-end industrial printing can realize plastic, certain metal or ceramic printing, materials that cannot be printed are relatively expensive and scarce. In addition, printers have not yet reached the level of maturity to support the wide variety of materials we come into contact with in our daily lives. Researchers have made some progress in multi-material printing, but unless these advances are mature and effective, materials will remain a major obstacle to 3D printing.

3. There is no advantage in large-scale production.

Since 3D printing technology has the advantages of distributed production, on the contrary, it does not have advantages in large-scale production. At present, 3D printing technology does not yet have the conditions to replace traditional manufacturing. In terms of large-scale and large-scale manufacturing, the traditional subtractive manufacturing method with high efficiency and low cost is even better.

4. Accuracy and quality issues.

Due to the inherent forming principle and development of 3D printing technology is not perfect, the accuracy (including dimensional accuracy, shape accuracy and surface roughness), physical properties (such as strength, stiffness, fatigue resistance, etc.) and chemical properties of the printed parts cannot meet the actual use requirements of the project. They cannot be used as functional parts and can only be used as prototypes, so their application will be greatly reduced.

For printed samples, it can also make make secondary processing to check part final assembly and cosmetic surface.

After 3D printing samples approved, there is many other way to move production for PVT, mass production etc.

Like Urethane casting, CNC machining, rapid tooling, mold making, etc.

SPM can provide one stop service for plastic and metal parts production with various secodary process.

Inquiry us if interested.