Industrial news

Why do aluminum parts deform?

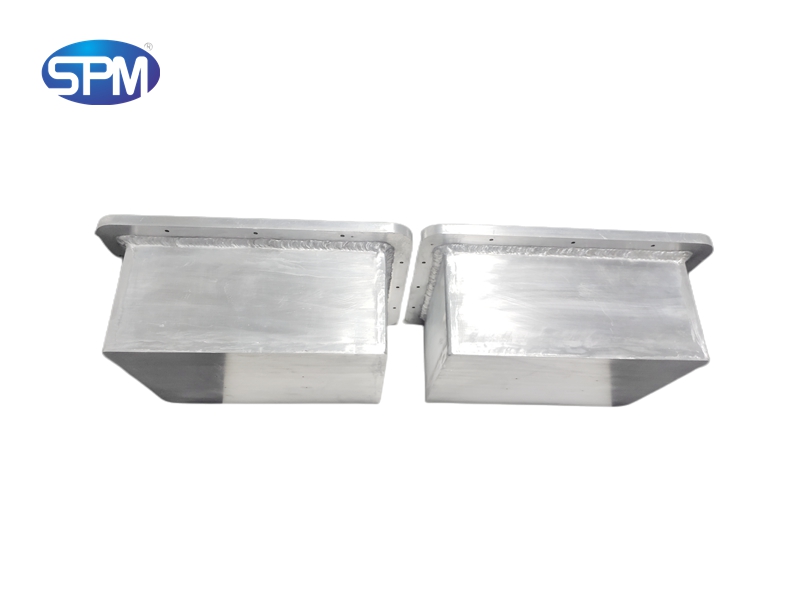

Why do aluminum alloy precision parts deform?

The processing deformation of aluminum alloy precision parts is mainly caused by factors such as rough material cutting force, deformation caused by cutting heat, deformation caused by internal stress, and deformation caused by clamping force.

We cannot allow deformed products to complete final assembly. Therefore, in order to reduce processing deformation, aluminum alloy precision parts processing manufacturers can take various measures to improve the process to achieve the purpose of reducing deformation. The first trick is to reduce the internal stress of the rough material.

First: reduce the internal stress of the rough material

First: reduce the internal stress of the rough material

Reduce the internal stress of the rough material.

Natural or artificial aging and vibration treatment can partially eliminate the internal stress of the rough material; or improve the cutting ability of the tool. Reasonably select the geometric parameters of the tool and improve the structure of the tool. The second trick is to improve the clamping method of the work piece.

Second: improve the clamping method of the workpiece.

For aluminum alloy thin-walled bushing parts, if a three-jaw self-centering chuck or collet is used for radial clamping, once the workpiece is loose after processing, it will inevitably be deformed.

At this time, the method of pressing the axial end face with better rigidity should be adopted. According to the positioning of the inner hole of the part, a self-made threaded mandrel is put on the inner hole of the part. Press the end face with the cover plate, and then support it with nuts. When machining the outer circle, clamping deformation can be avoided, so as to obtain satisfactory machining accuracy.

When processing aluminum alloy thin-walled and thin-plate workpieces, it is best to choose a vacuum suction cup to obtain a uniformly distributed clamping force, and then process with a small amount of cutting, which can well prevent the deformation of the workpiece.

Third: Arrange the process reasonably

In the high-speed cutting process, due to the large machining allowance and intermittent cutting, vibrations are often generated during the milling process, which affects the machining accuracy and surface roughness. Therefore, CNC high-speed machining can generally be divided into rough machining-semi-finishing-clearing-finishing.

For parts with high precision requirements, sometimes it is necessary to perform secondary semi-finishing and then finish machining. After rough machining, the parts can be cooled naturally to eliminate the internal stress generated by rough machining and reduce deformation.

In addition to the above reasons, aluminum alloy parts will also be deformed during processing. In actual operation, the method of operation is also very important. For parts with a large machining allowance, in order to have better heat dissipation conditions during processing and avoid heat concentration, symmetrical processing should be used during processing.

Related News

- What differences of Laser welding and ti 2023-10-26

- What meateiral suitable and what should 2023-10-12

- Common CNC metal machining materials 2023-09-15

- What plastic common usefor CNC machining 2023-09-04

- What is the difference of processing bet 2023-08-28

Categories

Contact us

Suntime Precision Mould Manufacturing Co., Ltd.

Contact:Victor Li

Mobile:+86 18098979853

Email:info@suntime-mould.com

Add:Block A, Sihai Yunchuang Building, Hou Ting community, Sha Jing Street, Bao An district, Shen Zhen, Guang Dong of China. Post code: 518104